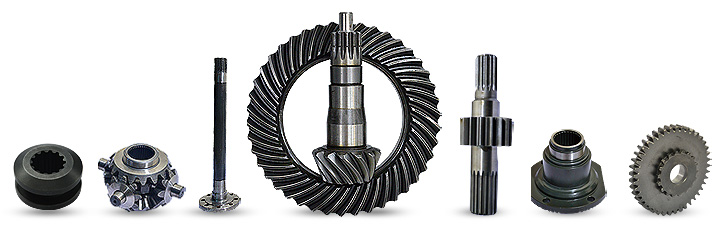

Him Teknoforge Ltd. is a leading manufacturer and supplier of a wide variety of quality Forgings and Machined Components (Blanks & Finished Heat Treated) like Gears, Axles, Shafts, Non Gear, Assemblies, Sub Assemblies, Spider Kits and repair kits. It commenced production in 1982 with a Forging Unit at Baddi, Himachal Pradesh, which was set up to supply quality forgings in bulk to various Original Equipment Manufacturers (OEMs) as well as Railways, Aftermarket and Exports.

- Our core values include customer satisfaction

- Quality consciousness

- Integrated growth, keeping in mind all shareholders

- Teamwork and an environment promoting regular brainstorming generating new ideas to meet customer demands.

Forging Division (Manpura, Himachal Pradesh)

This Plant was set up at Manpura, Himachal Pradesh in the year 2010 and has installed capacity of 30,000 tons/annum.

This Plant was set up at Manpura, Himachal Pradesh in the year 2010 and has installed capacity of 30,000 tons/annum.

This unit is fully equipped to test raw material in-house. Major testing equipments in this unit include Spectrometer, Micro hardness testers, Jominy value testers, Microscope and Optical Pyrometer to ensure a defect free product.

The company is installing 3 state of art presses and venturing into Warm & Precision Forging.

This unit is producing approx 1700 MT of forging every month.

The major machinery includes

- 3 Upsetter from 4 inch to 6 inch

- MPM-6300 B HUTA ZYGMUNT with Inductotherm 500 KW Induction Heater

- VMC & VTL for Die Making

- 200 Dia Ring Rolling

- Presses 1000 & 1600 Ton

Gear Division (Baddi, Himachal Pradesh)

Setup in 1996, the Baddi Gear Division is one of the main machining unit of HTFL with a manufacturing capacity of over 2,00,000 components per month and supplying to India's top OEM's.

The unit is spread out over 5 acres of area and key machines include

- CNC Turning & TMC with 4th axis

- Brother VMC's

- DMG 5-Axis HMC's

- CNC Liebherr Hobbing

- CNC Shaving,

- SQF - Heat Treatment & Inductotherm Induction Hardening

- Semi-Automatic Paint Shop,

- Electroplating

- Packaging and Warehousing

Forging Unit 1 (Pithampur, Madhya Pradesh)

This forging unit has installed capacity of approx 20,000 tons/annum and is currently using 70% of its capacity.

This forging unit has installed capacity of approx 20,000 tons/annum and is currently using 70% of its capacity.

Our both the forging units have CAD/CAM capability with VMC's, for die making and fully committed design and development teams who are pursuing value engineering at every level to enhance customer satisfaction and reduce prices.

The unit is also installed with CNC Turning centers and provides to be a one-stop shop for many of its customers.

Some major machinery includes

- 6.25 ton Hydraulic Hammer along with 1000 KW Billet Heater

- VMC - for Die making

- HT furnaces

Gear Division - Unit 2 (Pithampur, Indore)

This unit was acquired in 2011 and is spread across an area of 5 acres. The plant is equipped to manufacture Transmission Gears & Shafts for the Tractor and Commercial Vehicle segment and is mainly serving the aftermarket.

This unit was acquired in 2011 and is spread across an area of 5 acres. The plant is equipped to manufacture Transmission Gears & Shafts for the Tractor and Commercial Vehicle segment and is mainly serving the aftermarket.

Major Machinery includes:

- CNC Liebeher 6-Axis Hobbing, GCF, Turn Mill Centers, VTL upto 500 dia, Z-MAT VMC's

- Standard Room equipped with CMM & Contracer.

Gujarat Automotive Gears, Gujarat

The company has recently shifted the original plant and put up a state of art facility 15 kms from Baroda and has built a world-class warehouse of approx. 10,000 sqft.

The company has recently shifted the original plant and put up a state of art facility 15 kms from Baroda and has built a world-class warehouse of approx. 10,000 sqft.

GAG (Gujarat Automotive Gears, Gujarat) is primarily an export oriented unit with 98% of the revenue coming from selling versatile auto products in the aftermarket. The company has developed an organized network of reputed and loyal clientele not only India, but also in countries like Germany Italy, United Kingdom, Egypt, Sri Lanka, Singapore, Malaysia, Thailand, Belgium, Dubai, Australia United States of America etc.

Rigorous Research and Development activities, a careful customer demand analysis and a thorough knowledge of the industry brought to the table by its highly competent technical team have today steered Him Teknoforge Ltd.